With any construction project, there are a lot of moving parts to juggle at one time. In Mississippi State’s Building Construction Science program, the goal is to bring students together and teach them how to keep all the balls in the air.

Sophomore Ciera Presley understands this well as one of 40 students in the program’s Collaborative Studio, a combined class of BCS and architecture students who worked during the global pandemic to complete two modular tiny houses. The houses were designed and started during the fall 2019 semester by the then incoming freshman class. The initial project, which teaches students the fundamentals of constructing a building from the ground up, was part of the BCS freshman and sophomore studio courses.

“Learning textbook material is very different from going out and applying it because everything may seem perfect on paper, but it isn’t as perfect when you actually start building out on the job site,” the Batesville native explained. “Working on this tiny house project taught us that. Everybody had to work together and problem solve to make things run smoothly.”

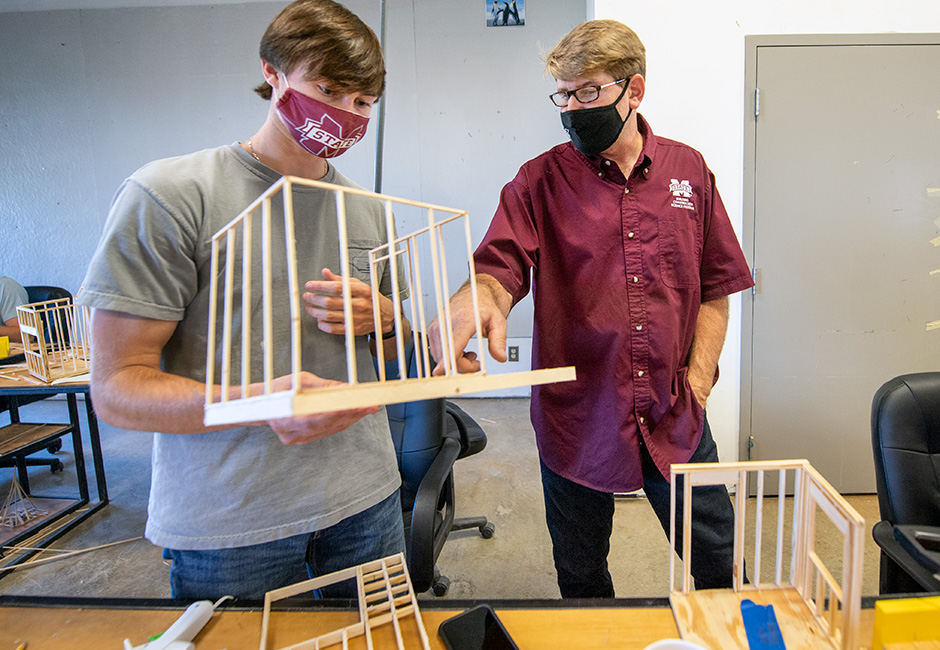

MSU architecture alumnus Lee Carson leads the studio as an assistant clinical professor, along with Richard Chenoweth, a visiting assistant professor. He said this modular, tiny house project provides the ideal applied learning experience. As part of the design process, the freshmen produce schematic designs, construction documents and shop drawings before any construction begins. Students had to consider various size and design parameters throughout the design and fabrication process.

Carson said some of the challenges of the design are small spaces, use of efficient materials, small modular pieces and transportation. Each of the buildings, he said, is designed and constructed of several “modules” or sections to allow flexibility in the design and fabrication, and easier transportation. Students also research materials and fabrication methods, and perform construction in two teams—each with a project manager, superintendent, foreman and crew members. During the construction process, the students are able to apply the knowledge they have gained while managing and collaborating with team members.

Mississippi State’s Building Construction Science program teaches freshmen the fundamentals of constructing a building from the ground up through a two-semester tiny house project. Throughout the design process, students consider various size and design parameters including small spaces, use of efficient materials, small modular pieces and transportation. They use this knowledge to produce schematic designs, construction documents and shop drawings before any construction begins.

The International Residential Code, which outlines minimum requirements for one- and two-family dwellings, defines “tiny houses” as being 400 square feet or less in floor area. Carson said this definition and a code for such structures were added in 2018 due to the growing popularity of the style.

The student-designed “tiny houses” are two stories. The first-floor area of just under 300 square feet includes kitchen, living, dining, bathroom and laundry spaces. The second floor has sleeping, storage and balcony spaces.

Carson said the current freshman studio is working on two more modular tiny houses, each consisting of a 160-200 square foot first floor with living, kitchen and dining spaces, and a 125-160 square foot second floor with sleeping, bathroom, laundry and exterior balcony spaces, as well as additional loft spaces.

“We had a very successful fall semester in freshman Studio-A and plan to have the new buildings finished this spring at the completion of freshman Studio-B,” Carson said, noting that in addition to constructing the buildings, students must also create a comprehensive document detailing the design and construction process and give presentations on the challenges they faced.

“We are thankful we have been able to complete these structures during this difficult time,” Carson said of guiding students through a global pandemic. “This project not only taught our students about materials and construction methods, but also equipped them with communication, organization and team management skills essential for their future education and work in the construction industry.”

George Ford, a professor and director of the building construction science program, credits support from the College of Architecture, Art and Design, as well as the BCS advisory board, with helping make the studio project possible. Companies with representatives on the board generously donate supplies to help students complete the tiny house project. Among others, these supporters include Glass Inc. in Meridian, Grant Roofing in West Point, F.L. Crane and Sons in Fulton, and Brasfield and Gorrie in Birmingham, Alabama. The BCS program also auctions off the student-produced houses each year, raising funds to provide future design-build experiences.

Students hone their research, design, communication, problem solving and team management skills through this applied learning experience. Each of the buildings is designed and constructed of several “modules” or sections to allow flexibility in the design and fabrication, and easier transportation. Students also research materials and fabrication methods, and perform construction in two teams. The BCS program auctions off the student-produced houses each year, raising funds for future design-build experiences.

Michael McGraw, a 1988 MSU business administration graduate from Brandon, has purchased five modular houses from the studio in previous semesters. He said he plans to use them for a housing development he’s working on in Clayton Village, just up the road from MSU’s Starkville campus. He envisions offering the completed homes as more affordable, private alternatives to traditional game day condominiums or apartments.

“The students are creating really neat architectural designs for these houses,” McGraw said. “My favorite is a cypress building, one of the earliest ones they built. It looks like a church because it’s got the big, vaulted ceiling. It has a porch on the front with a metal roof, and there’s a skylight going down the middle. They did a good job with it.”

McGraw, who comes from a family of Bulldog graduates, said he hopes to continue supporting student success through future tiny house purchases. Such support is crucial in ensuring that students like Presley have more opportunities to gain hands-on construction experience.

“I’ve been enjoying myself in the BCS program at State because the professors are really nice and easy to talk to. They are always ready to listen and be inclusive,” Presley said. “If you have a passion to do construction work, you should go for it. Be ready to face challenges and let them build you up. If you have a strong will, you can do it.”

By Sasha Steinberg, Photos by Megan Bean