MSU research center paves the way for next generation of composite materials, aerospace

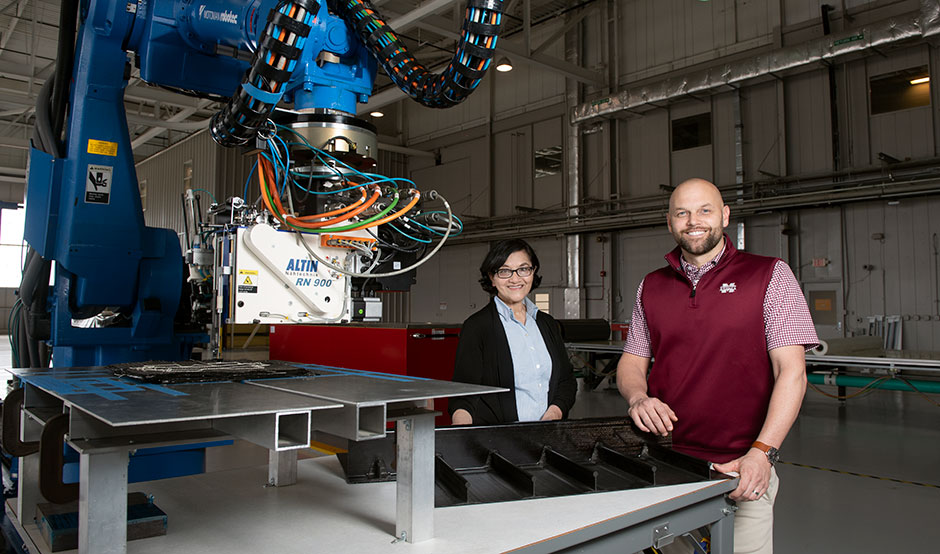

Rani Sullivan (left), a professor of aerospace engineering, stands in the Advanced Composite Institute with its director Christoper Bounds.

In the early 1990s, a Mississippi State team designed and fabricated the world’s first business jet made entirely of composite materials. These composites allow planes to safely fly at a much lighter weight, reducing fuel costs and increasing cargo capabilities.

Composites are two or more distinct materials combined to make a stronger and more resilient material. As they have become more commonplace in aerospace and other industries, an MSU research center is advancing the next generation of composite technology. MSU’s Advanced Composites Institute, which celebrated its grand opening in 2019, is home to the Marvin B. Dow Stitched Composites Development Center, which is pioneering a new production process for composites that improves durability and further reduces the weight of the materials.

ACI and the Stitched Composites Development Center were established after MSU was selected by The Boeing Company to create a new lab to advance composite structures technology.

Christopher Bounds joined MSU in the summer of 2020 to serve as director of ACI. With faculty from several academic departments conducting fundamental research to advance the field and a staff of scientists and engineers available to conduct applied research for clients, Bounds said ACI serves as a valuable connection between academia and industry. It also gives students the opportunity to solve engineering challenges for clients, giving them project management experience as they begin their careers.

“If companies have a problem that involves advanced composites, we can solve it. We’ll come up with a proposal then fabricate and execute it.” ~ Christopher Bounds

Bounds noted the potential for the new generation of composites will continue to go grow as fundamental and applied research validating the materials takes shape.

“If companies have a problem that involves advanced composites, we can solve it,” Bounds said. "We’ll come up with a proposal then fabricate and execute it. We can even provide the evaluation and testing. So, if our partners bring us a problem, we’ll provide a validated solution before they leave.”

ACI is housed at MSU’s Raspet Flight Research Laboratory, building on the university’s legacy of innovation in aerospace research and development. ACI’s capabilities can bolster Raspet’s research on both manned and unmanned aircraft.

“Today, nothing is more important to the advancement of aircraft design, manned or unmanned, than strong, lightweight construction materials that result in improved overall flight performance,” said Tom Brooks, Raspet's interim director. “Through its leadership in advanced material design and manufacture, ACI continues Raspet’s long standing tradition of improving aviation safety through applied research.”

In addition to aerospace applications, ACI can facilitate research for any area that could benefit from advanced composites, such as automotive manufacturing, marine structures, ballistics and renewable energy.

“For example, if more people move from internal combustion engines to electric cars, those batteries are very heavy,” Bounds said. “As you add weight in one area, you need to take weight away from something else to maintain performance. That’s what composites do for you. Metal is strong, but metal is really heavy. Composites are also strong, but they are much lighter.”

Rani Sullivan, a professor and the Richard H. Johnson Endowed Chair in Aerospace Engineering, said she has has shifted some of her research to stitched composites to take advantage of ACI’s capabilities. Sullivan was part of the engineering team at Raspet that worked on the first all-composite jet. She later pursued her master’s degree and doctorate at MSU before becoming a faculty member in 2005.

A current research project of Sullivan’s uses optical fibers embedded within the stitched composites to monitor structural health, allowing researchers to see damage to the material before it is visible externally.

“My research group is trying to answer fundamental questions regarding stitched composites,” Sullivan said. “For example, how do these structures behave under different types of loadings and different environmental conditions? How do cracks grow in these structures? How do we increase the durability of these structures? By embedding optical fibers, we are able to map how internal cracks grow. You don’t want cracks on something going to outer space.”

Bounds said he wants to ensure ACI complements the capabilities of MSU’s existing research centers, as well as other universities in the state. He also sees economic development potential as ACI can help Mississippi companies in multiple sectors develop new manufacturing capabilities.

“If Mississippi grows, MSU grows,” Bounds said. “Places like this institute and the technology we have provide a global audience for promoting Mississippi and all of the assets and capabilities we can bring together. When we all work together, the sky is the limit.”

MSU again leads Mississippi’s research universities, remains in nation’s top 100 in latest NSF survey

The latest survey from the National Science Foundation again affirms Mississippi State’s status as the state’s leading research university.

Among all institutions in the NSF’s recently released Higher Education Research and Development Survey, MSU moved six spots up the rankings to No. 92 nationally with more than $264.5 million in research and development expenditures for fiscal year 2019, an increase of $20 million from the previous year. An NSF top 100 research university for nearly two decades, MSU boasts 30 disciplines and subdisciplines ranked in the top 100 in the latest report. The university has reported an increase in research and development expenditures for six consecutive years, capping a decade that saw MSU report $2.3 billion in research expenditures from FY10-FY19.

With a diverse research portfolio, MSU ranks in the top 15 nationally in both agricultural sciences (12) and social sciences (15). The university has been in the top 5% of all universities for agriculture research for approximately two decades. For the eighth consecutive year, MSU leads all Southeastern Conference universities in social sciences research funding. MSU leads the state with 4,044 research personnel, including 605 principal investigators.

“It is exciting to see continued growth in our research funding, especially in an increasingly competitive environment,” said MSU President Mark E. Keenum. “Our world-class faculty and staff are advancing their fields, moving our state forward and providing opportunities for students to participate in cutting-edge research. Our dynamic R&D capabilities are an economic development asset for Mississippi as we work to develop, attract and support industries in key sectors of our state’s economy such as agriculture, manufacturing and aerospace. I’m very proud of the significant impact that our more than a quarter of a billion dollars in expenditures has in our state, nation and world.”

By James Carskadon, Photo by Beth Wynn